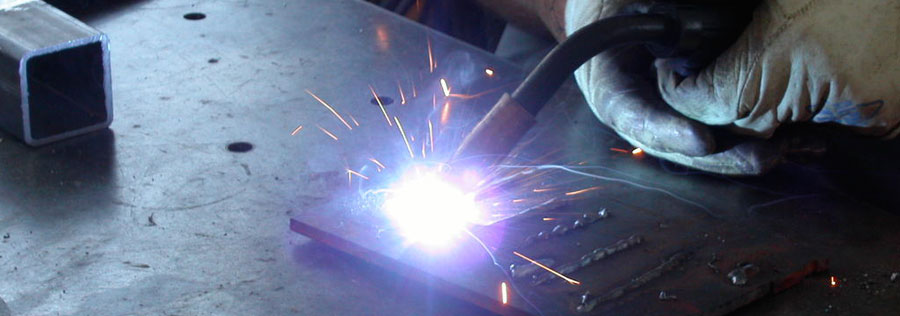

Welding Service

Welding is a fabrication process, whereby two materials, usually metal, are joined together. At the end of the welding process the two pieces of metal become one continuous solid.

The two forms of welding most common to our workshop are TIG & MIG & Richards Sheet Metal have a highly skilled team that are well equipped to tackle even the most complicated of welding jobs.

Our Welding Process

The tradition form of welding is a process known as forge welding, used for centuries when joining iron and steel by heating and hammering. Things have moved on since then and Richards Sheet Metal are always at the forefront of changes to welding methods.

There are many factors that can have an effect upon the welding process. A prime example would be that different metals may require different types of welding due to the reflectivity of the metal surface. Finish is also a factor to be taken into consideration, as certain welds can be unsuitable when performing fine work.

The Various Methods of Welding

There are two main forms of welding that are commonly used by us at Richards Sheet Metal, which are Tig & Mig welding. Both forms have there strengths & weaknesses & are suited in different ways to different jobs, but both methods are used within our workshop on a daily basis.

When it comes to choosing a welding process, there is, unfortunately, no single welding process for all applications. It is therefore down to the judgement & skill of our welding team to consider the advantages of one process over another & then make their decision.

Mig Welding & Tig Welding

Mig welding, or Mag welding as it is sometimes referred, is one of the easier welding processes to learn & is widely used on thinner materials. It also has the advantage when it comes to achieving cleaner welds without the need for additional cleaning & slag removal from the welds.

Tig welding is not as easy to learn as Mig welding, but it has the advantage of providing the highest quality & more precise welds. Tig welding also allows for the adjustment of heat input while welding by use of a remote control.

Please contact us 01282 691068 for a quote, or simply fill out the forms provided & a member of our team will get back to you within 24 hours.

Let Us Help With Your Next Project

CONTACT US

With over 40 years experience in the sheet metal industry, Richards Sheet Metal are able to create a countless number of lasered sheet metal products for use in a variety of industries.

Continual investment in the latest metal cutting and shaping technologies puts us in a leading position within the UK.

Contact Us Now on 01282 691068 and get a free quote for your next project...

Precision Parts

Latest Technology

Fast Turnaround

Friendly Team